Description

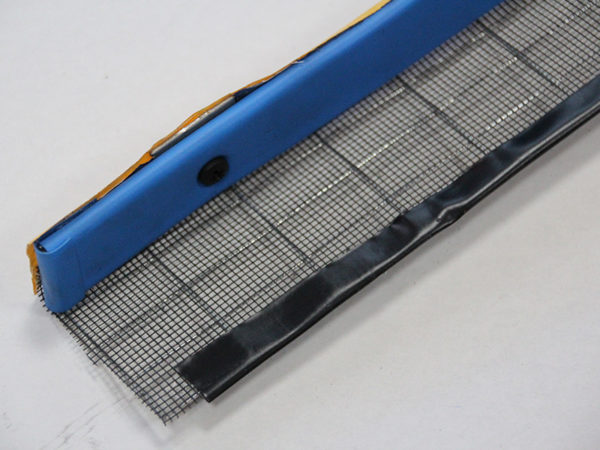

Rodent Protection Cavity Barriers

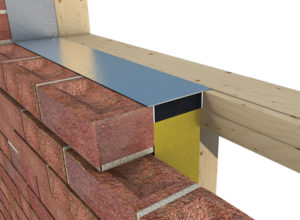

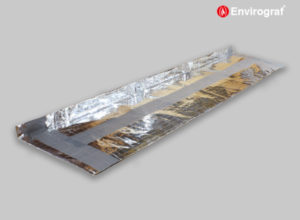

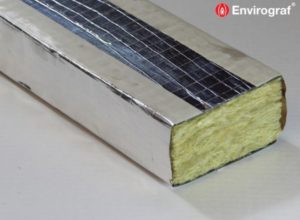

Cavity Barriers are pieces of fire-stopping material. They fit within the cavity of a building at each floor horizontally and party wall in a verticle position. The material provides compartmentation. Both the flames and heat cannot be transferred to other compartmental areas. Throughout the life of the building, the Cavity Barrier will remain fixed in place. In the event of a fire, the intumescent material expands and seals off the gaps. Additionally, the horizontal barriers allow for a ventilation gap within the cavity. Subsequently closing when the intumescent expands.

Our Cavity Barrier range at Envirograf® offers superb protection to your building by providing fire stopping. Explore the Cavity Barrier range online.